Industry 4.0 Labo-cer

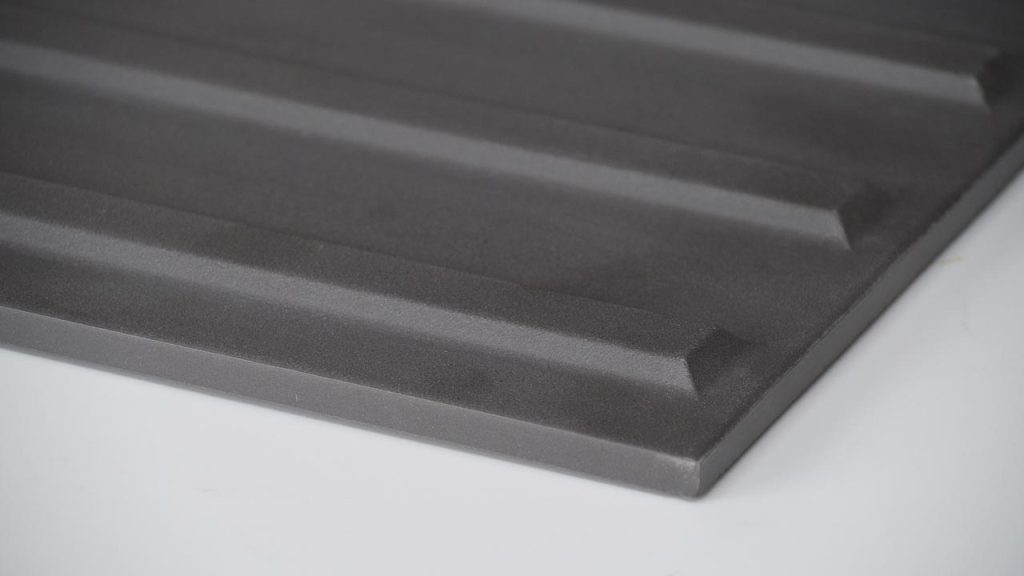

Ceramic technology is constantly evolving, at Labo-Cer, there has always been a focus on the development and transformation of new automations. The use of state-of-the-art equipment with systems aligned to Industry 4.0, as well as modulation of the pressing process, allow the production of special pieces with very accentuated textures and, in terms of precision and consistency of physical features, with all the advantages deriving from the dry pressing method.

Raw material

Silos in the ceramic industry are impressive symbols of efficiency and organisation, built to optimise the production process of ceramic materials. Inside, they have a labyrinth of pipes and distribution systems that regulate the flow of incoming and outgoing materials. These sophisticated mechanisms are designed to ensure precise dosing and even distribution of materials throughout the production process, guaranteeing the consistency and quality of Labo-cer’s end products.

At the heart of the ceramic industry, the silos represent an anchor of stability and reliability, silently supporting the production cycle while the frenetic activity of the industry continues around them.

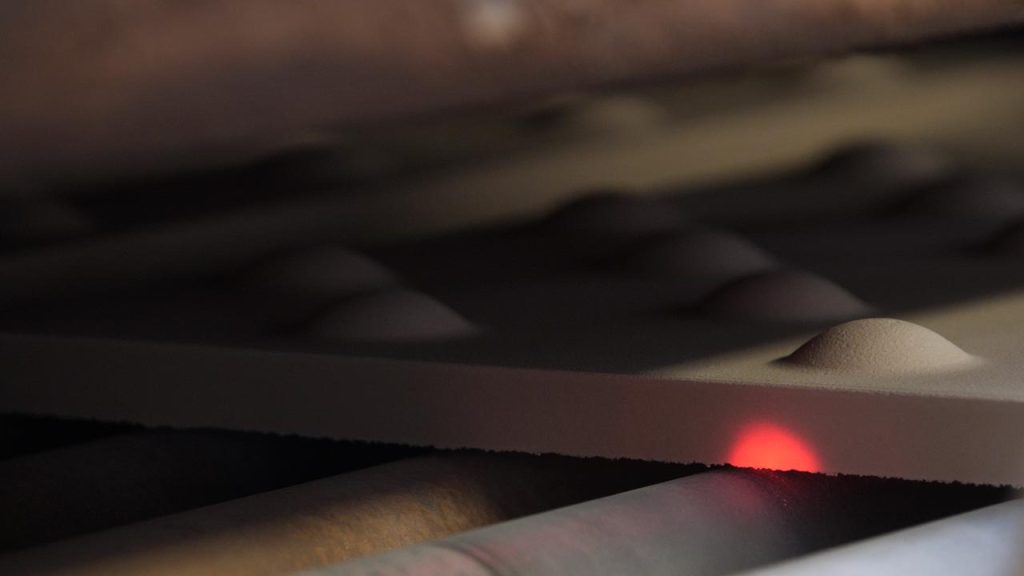

Presses

Sacmi presses have advanced electronic control systems that enable unparalleled precision in the tile-forming process. These systems constantly monitor pressure, temperature and other critical parameters, ensuring a uniform and consistent quality of the end product. Thanks to these controls, every tile produced strictly adheres to the highest quality standards.

The ability to process a wide range of materials, from porcelain stoneware to glazed ceramics, makes these machines capable of adapting to the specific requirements of each production process.

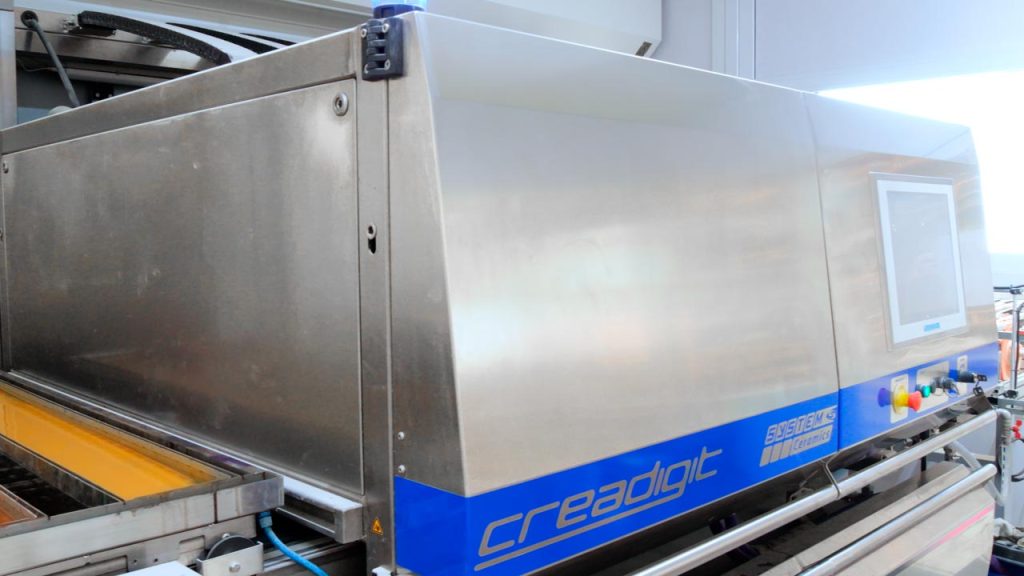

Digital printers

System digital printers are at the pinnacle of technology in ceramic printing. These cutting-edge machines embody innovation and precision, offering advanced solutions for the production of high-quality ceramic tiles. With an array of high definition printheads and advanced control systems, these machines are able to transform the most complex design ideas into tangible reality, with unprecedented colour fidelity and sharpness.

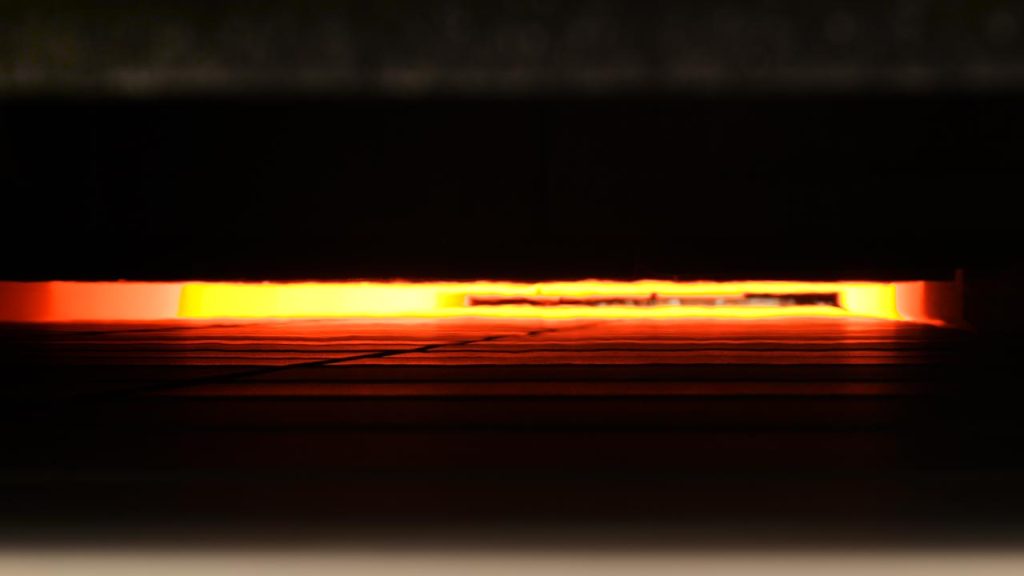

Roller kiln

The roller kiln is the beating heart of firing operations in the ceramic industry, an essential machine that embodies the fusion of tradition and modern technology. It is a cornerstone in Labo-cer’s entire production process.

Its rollers, arranged along its length, serve as a mobile platform for conveying the tiles through the firing process. This design allows even heat distribution and uniform firing, ensuring the highest quality of the finished products.

The kiln also uses temperature sensors and automated control systems to regulate the internal temperature and firing time exactly, ensuring that each tile emerges with the right strength, durability and colour.